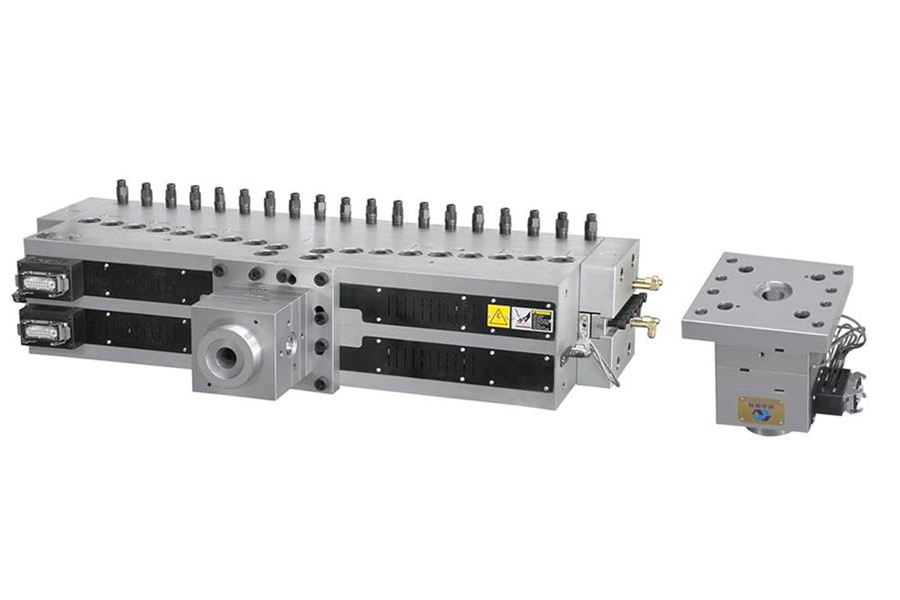

PVC, WPC Co-extrusion Mould, Co-extrusion Distributor

|

Npe |

PVC, WPC pa roj carbon monoxide-EXTRUSION MOULD, CO-LUB TSHWJ XEEB EXTRUSUTOR |

|

Qhov Coob |

Txheeb cais |

|

Kab noj hniav |

Ib leeg-txheej |

|

Cov Khoom Siv Yas |

PVC / WPC |

|

Daim ntawv thov tseem ceeb |

Cov tub ntim khoom hauv chav tsev, chaw ua haujlwm kho kom zoo nkauj, pawg ntoo pem teb, pawg thawj coj saib rooj tog, tsev tsim qauv, tais tais, ntawv dai. lwm yam |

|

Thickness |

5-25 hli |

|

Yam khoom |

PVC, WPC pa roj carbon monoxide EXTRUSION Board |

|

Pwm Nyiaj Txiag |

1 xyoos |

|

Pwm Txheej Txheem |

Tuag lub taub hau, calibrators, cua sov pas nrig |

|

Lub voj voog ntau lawm |

30-45 hnub |

|

Kho deg |

Polish |

|

Pob & xa |

Poly wood rooj plaub rau kev xa tawm, txhua pwm yuav ntxuav ua ntej yuav ntim. |

1. Txhim kho cov khoom lag luam tawv hardness los ntawm cov npoo loj.

2. du nto thiab tsis siv tshuab kev ntxhib los mos.

3. Txo cov nqi ntau lawm.

4. Cov hlau zoo dua, Cov Khoom Zoo.

5. Tus nqi tsim nyog.

6. Muaj zog pab pawg engineer Txhawb & R.

7. Kho raws li tus neeg thov.

8. Kev hloov kho cov khoom lag luam thiab kev tsim kho kom raws sij hawm.

9. Lub sijhawm khoom xa tuaj yog peb qhov yuav tsum tau ua.